With pollution control now being a mandate for all industrial units, Electrostatic Precipitators (ESP) have assumed a great significance due to their capability to efficiently remove particulate matter from the air and other gases. With our unique ability to develop new profiles with very short development cycles, Pennar Industries serves the ESP electrode requirement for a wide range of industries.

How ESP Electrodes work?

An electrostatic precipitator (ESP), or electrostatic air cleaner is a particulate collection device that removes particles from a flowing gas (such as air) using the force of an induced electrostatic charge. Electrostatic precipitators are highly efficient filtration devices that minimally impede the flow of gases through the device, and can easily remove fine particulate matter such as dust and smoke from the air stream. In contrast to wet scrubbers which apply energy directly to the flowing fluid medium, an ESP applies energy only to the particulate matter being collected and therefore is very efficient in its consumption of energy (in the form of electricity) Source - Wikipedia

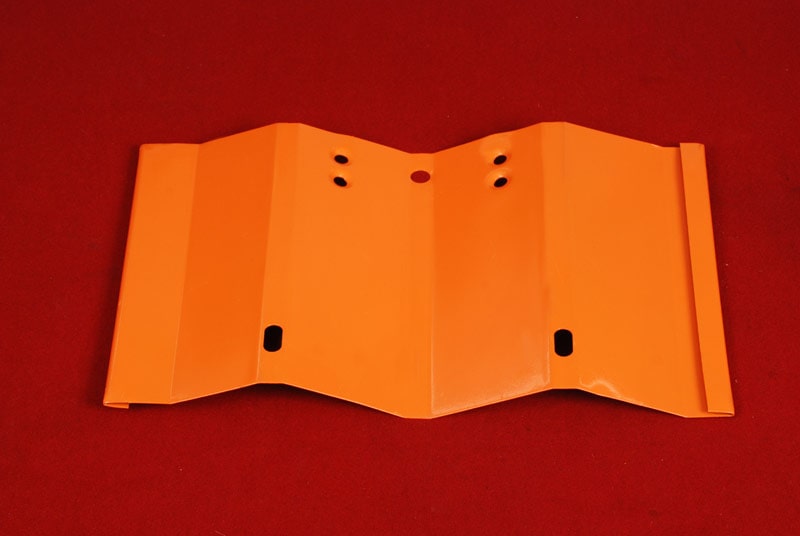

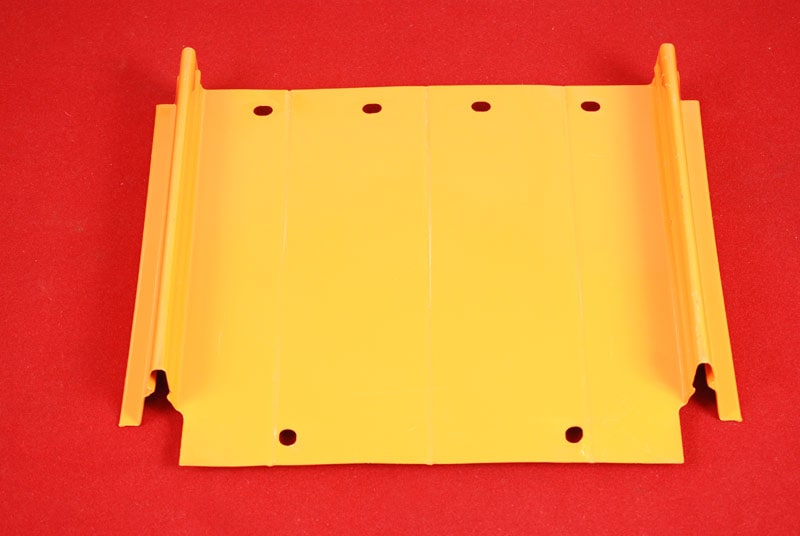

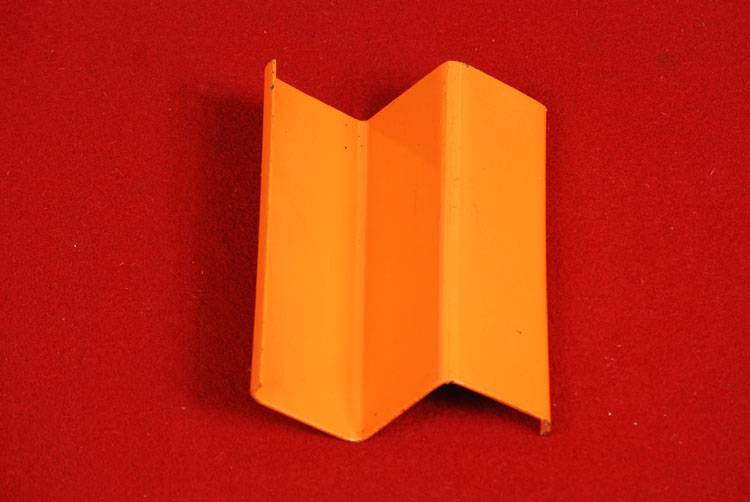

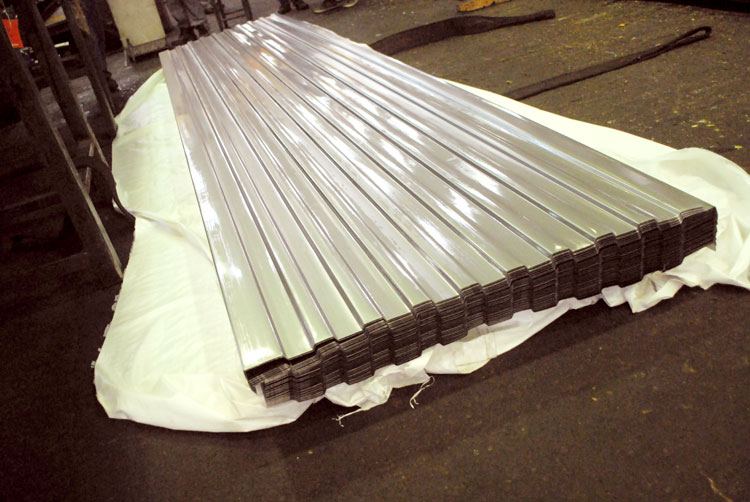

COLLECTING ELECTRODES

Collecting Electrodes are in the form of parallel plates, simply the collector’s inner walls that collect particles in the flow of gas moving through a collector chamber. The plates or inner walls serve as grounded electrodes that collect particles. The collecting electrodes are vibrated to loosen the particles, which fall into hoppers for collection and disposal.

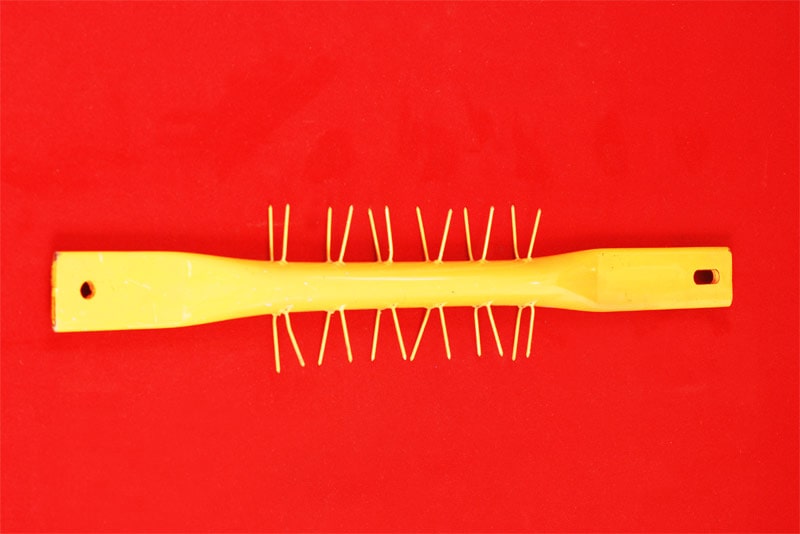

DISCHARGE ELECTRODES

These electrodes are insulated electrically from the rest of the chamber and charged with high direct current. The electrical charge ionizes the suspended particles, causing them to move toward the collecting electrodes. Opposite high voltages (plus and minus) are charged on two plate grids. The positive grid charges the particles and the negative grid attracts (collects) them.

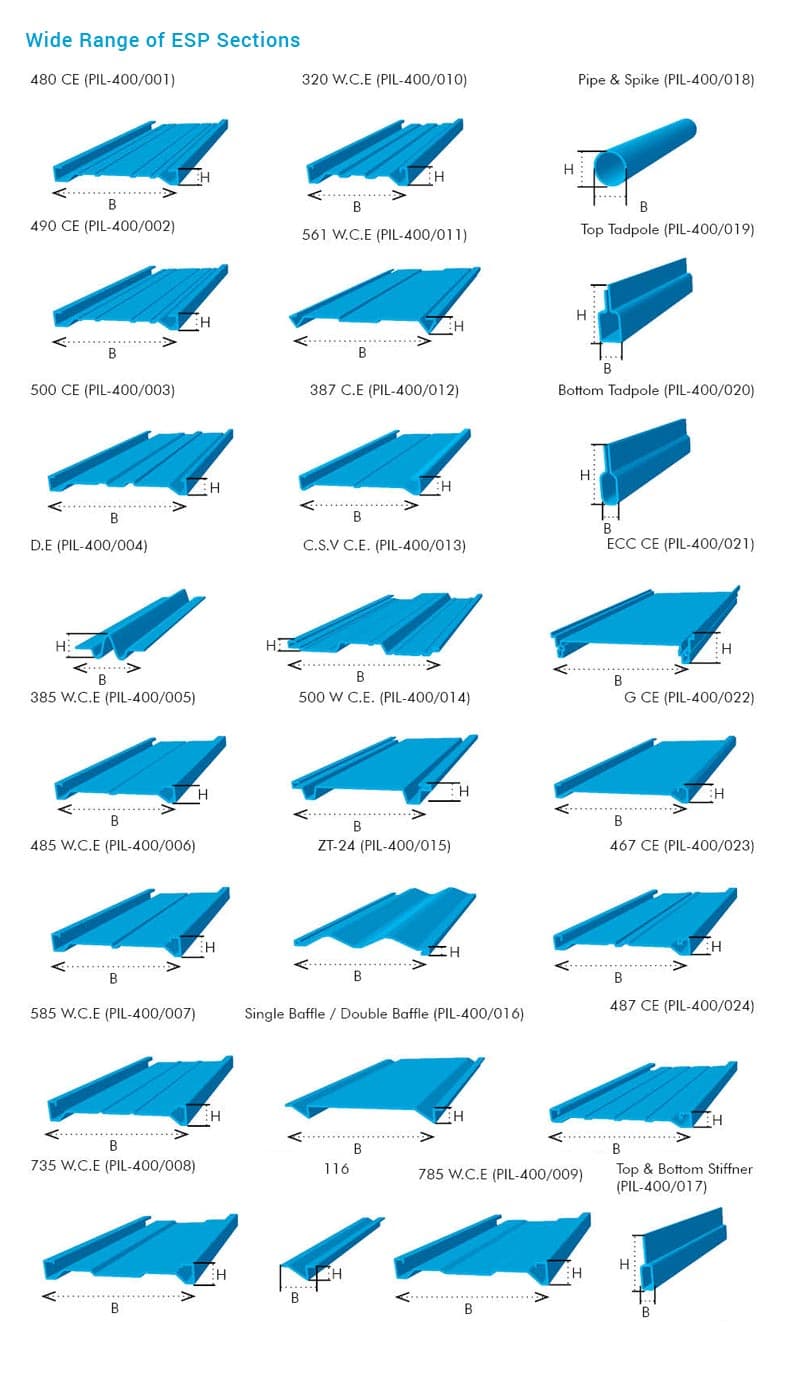

Pennar Industries ESP Electrodes are preferred by OEMs across India and provide many advantages for our customers:

- High quality Electrodes with the capability to withstand high temperature (up to 400 Deg. C).

- Available in a wide range of thickness and lengths (Length up to 15 meters and Thickness from 1.2mm to 1.6mm).

- A wide range of profile designs to choose from, which are appropriate for a majority of industries (from 387 mm to 2768 mm).

- Apart from the standard type of profiles, we have capability to manufacture required tools for new profile designs.

- Consistent quality with strong commitment to on-time delivery.

Collecting and Discharge electrodes are used in various industries as:

- Power and Industrial Boilers firing (Coal/ Lignite/ Oil/ Orimulsion/ Biomass and other fuels)

- Iron & Steel industries

- Non-ferrous Metallurgical industries

- Cement industry

- Incineration plants

- Glass smelting

- Pulp & Paper plants, etc

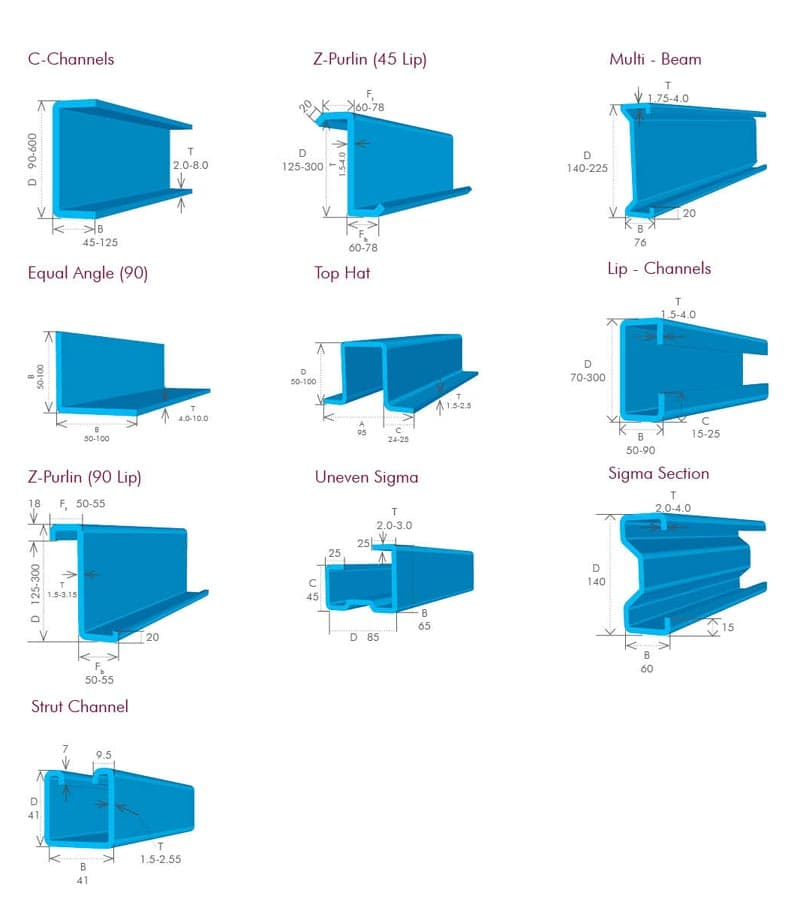

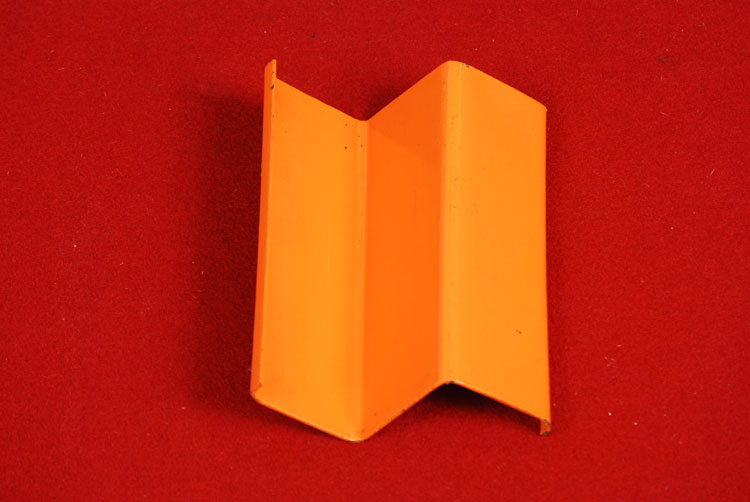

Collecting Electrode: Sigma / Baffle Type

| Material |

C.R - IS 513 Gr. D / Corten Steel |

| Profile width |

300 to 2550 mm |

| Length |

Up to 15000 mm |

| Thickness |

1.2 - 1.6 mm |

Discharge Electrode: Pipe & Spike / Barb Type

| Material |

ERW Tube IS 5986 / IS 513 Gr.D |

| Profile OD |

Up to 50.8 mm |

| Length |

Up to 15000 mm |

| Thickness |

1.2 - 1.6 mm |

Product Specifications